Essential of Packaging Design Elements from printing perspective.

I will start this blog with an analogy. A catalyst in a chemical reaction triggers the elements that speed-up the desired output. A right packaging design does the same thing to the complete packaging development on time. Let me give you the relatable instance. Maximum designers work on the principles of commercial printing or paper-based printing concepts. Hence, flexible packaging design on gravure printing encounter challenges.

For me, Packaging design is an essential part which is often underrated in technical process. I was able to realize its importance a little late and want to share it with you.

I have been fortunate to work along with major FMCG / CPG brands in India. However, as a Shrink Sleeve Expert, it is difficult to comment on packaging designing concept which is essentially the part of brand’s perspective. Yet, to give a practical outlook on the same, I want to highlight a few points that seem critical from a printing perspective.

My work experiences have given me chance to explore technical and non-technical part of printing packaging execution. All this knowledge has led me to write 3 well received packaging books and be at the international platform like AWA Conference in Amsterdam that happened last year. While covering vivid aspects, I started to understand the nitty-gritties of perfect packaging.

In this blog, we will cover the essential of packaging design. Before I start, here’s a small reminder that these points are from printing perspective. You may differ from my views as a brand owner despite that they are critical to efficacies of packaging.

- Label details (Container Shape + KLD)

Holding basic idea on product’s container shape is first step. It is one such aspect that make or break your packaging. I have seen changes in the design happening on printing stage because of this. Bottle shape, curves and contours adds a lot to the brand’s appeal and to the meticulous work on design. Other point is Keyline drawing which is essential part that clear the air about successful packaging development. It is one of the most technical part or can also be termed as the trickiest step before final print. It receives maximum correction for perfect output. Brands must consider them as the basic grid line that decide finish.

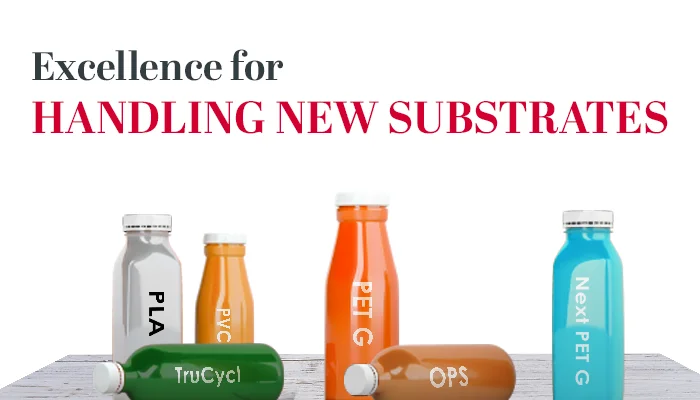

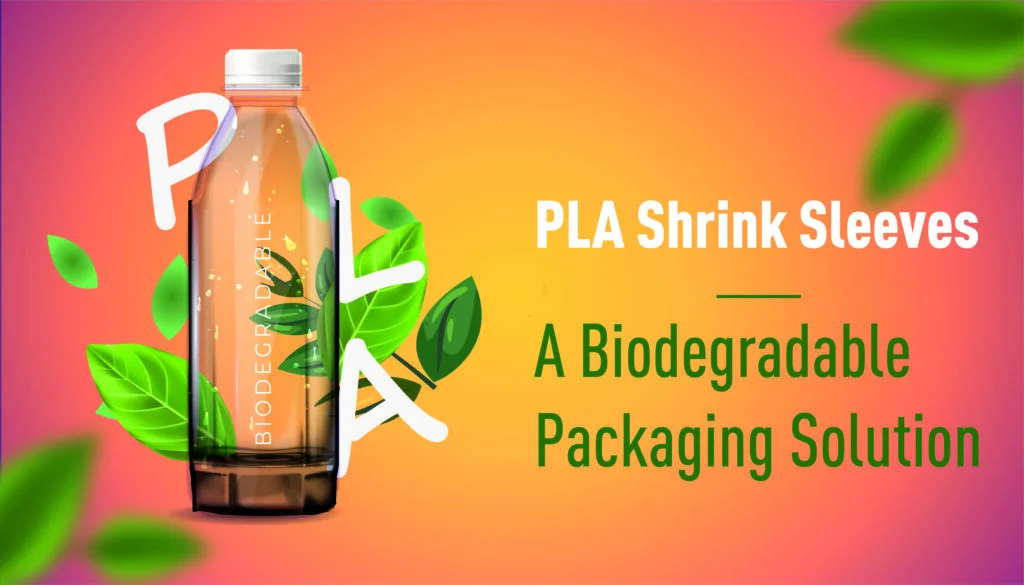

- Material & Finish (Special effect + Substrate)

Understanding of substrate and finishes of the shrink sleeve to ensure compatibility with printing techniques is important. Different substrate has different properties which offer compatibility with container and printing machines. Special effects and Embellishments need specific details during printing which cannot be overlooked. It is important to understand the special effects with printing compatibility.

- Printing Considerations (Printing Type +Pantone)

Type of printing is another factor to consider. Decision to opt for specific type of printing not only covers the financial aspect but also include the execution part. Gravure printing is opted where product have high quantity. Digital & Flexo has its own preferences according to the printing requirement. Having a clear understanding of number of pantones used in design will give clarity. Common pantone shades can be preferred to avoid wastage of inks. Providing the specific pantone number to the printer will resolve a lot of issues later.

- Legal Requirement

Adhering to mandatory government norms and legal regulation on the product packaging design is vital. Because of stringent laws and requirements, designing concept can be tweaked. It is imperative to be in compliance with these legal matters like warnings, product ingredients and information etc.

- Mock-Up & Prototype

Prototype or Mock-up are the test runs that defines your packaging design. It is crucial to visualize the design than to presume in mind, prior to final execution. Therefore, Mock-ups provide a practical solution to flawless execution. Our R&D team with latest Digital printing machine will provide you the quick Mock-up and prototype for clarity on execution.

Above are the points that are crucial for packaging development. I could extend and might add a few points more. But value comes with preciseness. Let’s us catch up again for more insightful lesson